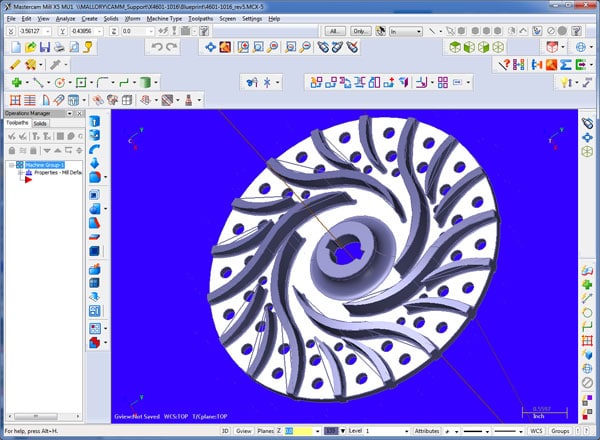

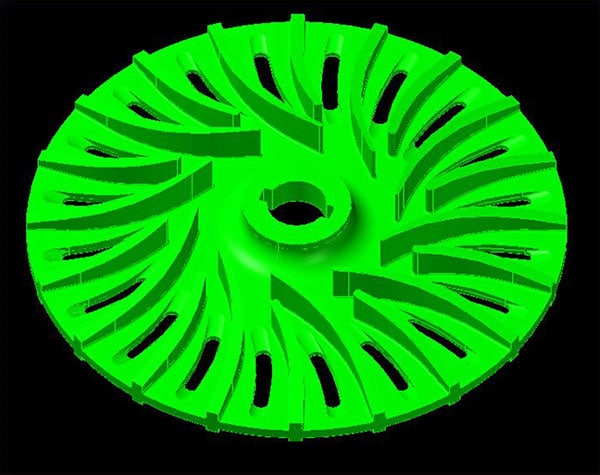

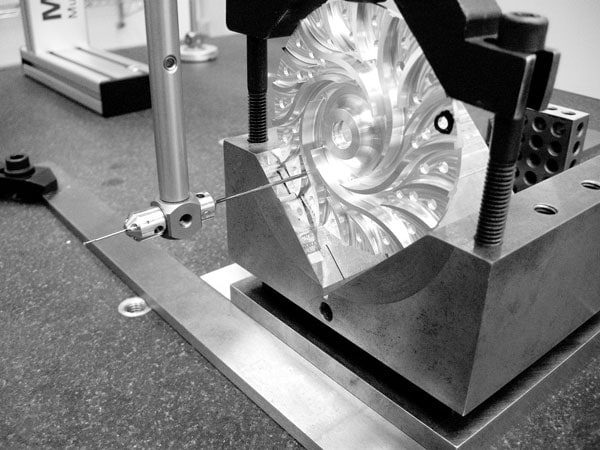

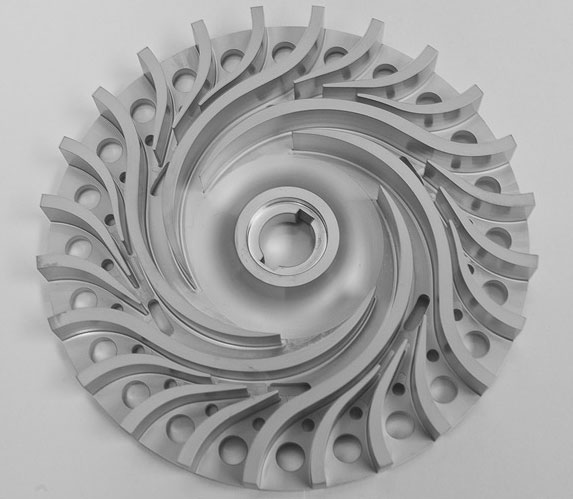

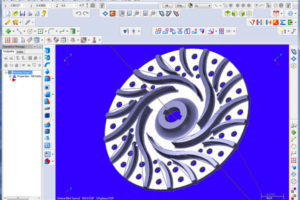

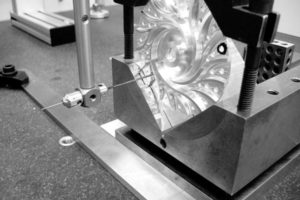

Recently, a client from the aerospace industry contracted Mallory Industries, Inc to produce 10 aluminum centrifugal pump impellers. These parts are used as components of a fuel pump. We combined our 2-axis CNC turning capabilities with our 3-axis CNC high-speed milling technology to produce these parts. We also performed wire EDM to create the intricate keyways.

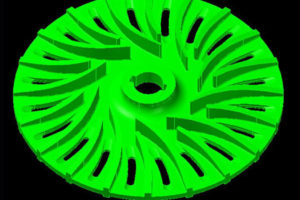

During the production of these impellers, our advanced machinery met ultra-precision tolerances as close as ± .00025″ for all diameters, with a squareness tolerance of .0005″. The finished parts measured 5″ in diameter and .7″ in material thickness, and possessed a smooth, 32 RMS surface finish. Fulfilling both of our client’s specific standards and specifications, each component featured .5″ tall vanes, and a profile of .005″. The impellers were also able to spin at speeds of 14,000 RPM.

By combining our advanced wire EDM and CNC machining technology, Mallory Industries was able to produce 10 precision centrifugal pump impellers for the aerospace industry that satisfied all of our client’s requirements for quality, design, and performance.